Cheese Making Process

Milk Collection

Factory Reception

Milk is received daily at our facility through an automated process to keep its properties intact. Additionally, continuous quality checks are performed to ensure the milk’s excellence.

Pasteurization

The milk is heated to 72°C for 16 seconds to ensure maximum hygiene. This process eliminates potential germs without compromising its nutritional value.

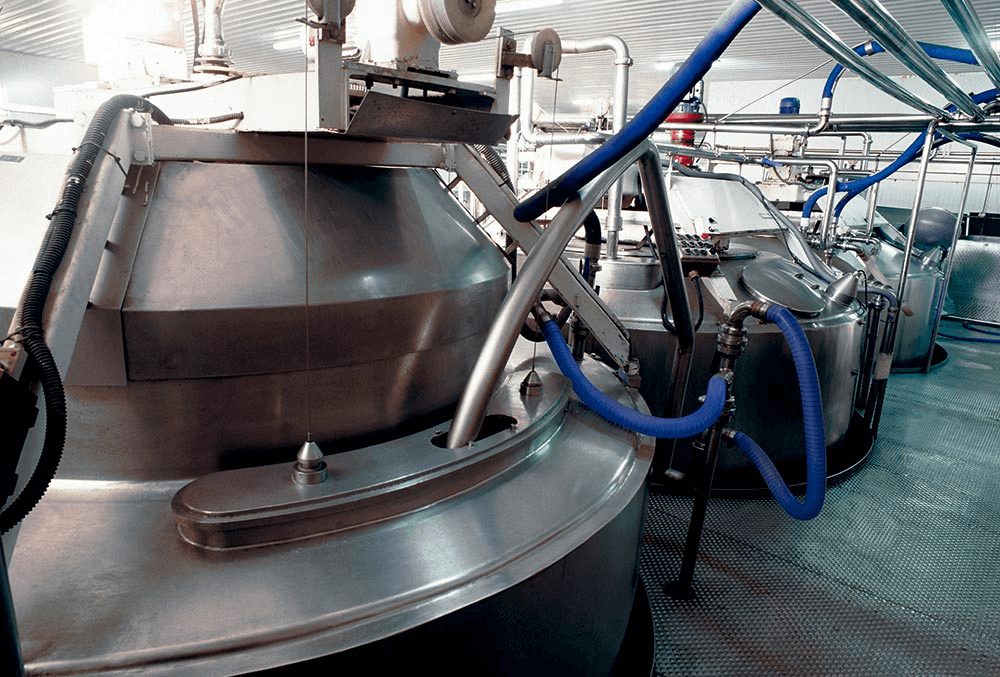

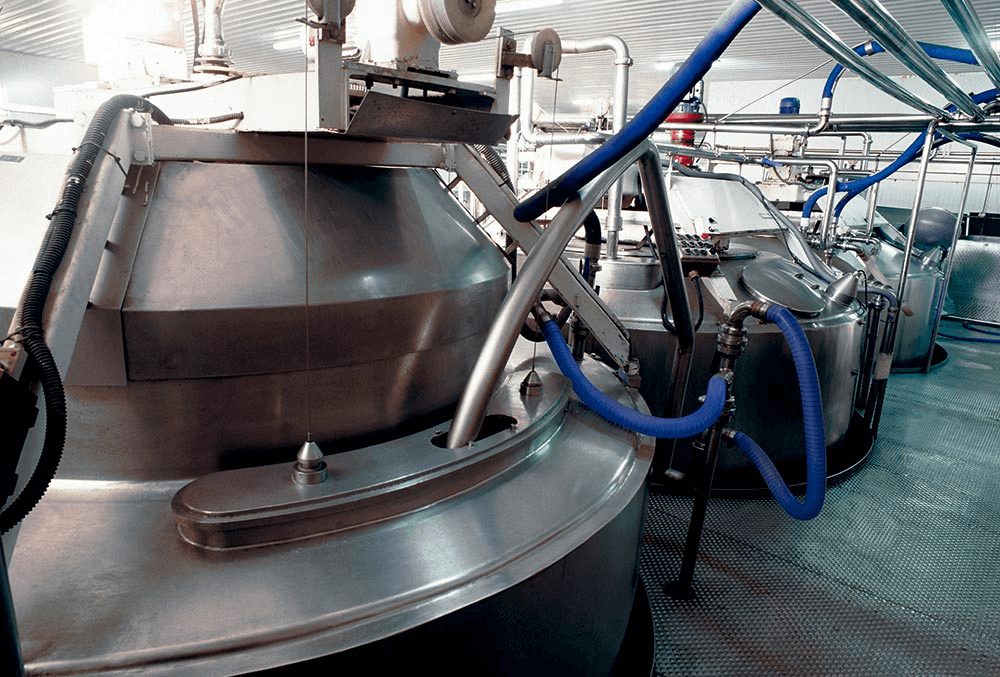

Work in the Vat

Pasteurized milk is placed into vats, where starter cultures are added to acidify and flavor the cheese, followed by rennet to coagulate the milk. The curd is then cut, stirred, and heated.

Molding

The curd is placed into cylindrical, micro-perforated molds that facilitate further whey drainage.

Pressing

During this stage, the cheese continues to expel whey with the help of presses and takes on its distinctive cylindrical shape.

Salting

The cheese is removed from its mold and placed in brine tanks, where it remains for hours to up to two days, depending on the type and size of the cheese. During this process, the cheese loses water and absorbs salt, which helps form the rind and improves its resistance and shelf life.

Aging

The cheese undergoes drying and aging, which can last up to two years, varying by cheese type. Throughout this period, the cheese must be regularly turned to ensure even drying.

Packaging

In this stage, the cheese is prepared for sale and shipping. It is cut, packaged, labeled, and palletized into boxes for distribution.

Milk Collection

Factory Reception

Milk is received daily at our facility through an automated process to keep its properties intact. Additionally, continuous quality checks are performed to ensure the milk’s excellence.

Pasteurization

The milk is heated to 72°C for 16 seconds to ensure maximum hygiene. This process eliminates potential germs without compromising its nutritional value.

Work in the Vat

Pasteurized milk is placed into vats, where starter cultures are added to acidify and flavor the cheese, followed by rennet to coagulate the milk. The curd is then cut, stirred, and heated.

Molding

The curd is placed into cylindrical, micro-perforated molds that facilitate further whey drainage.

Pressing

During this stage, the cheese continues to expel whey with the help of presses and takes on its distinctive cylindrical shape.

Salting

The cheese is removed from its mold and placed in brine tanks, where it remains for hours to up to two days, depending on the type and size of the cheese. During this process, the cheese loses water and absorbs salt, which helps form the rind and improves its resistance and shelf life.

Aging

The cheese undergoes drying and aging, which can last up to two years, varying by cheese type. Throughout this period, the cheese must be regularly turned to ensure even drying.

Packaging

In this stage, the cheese is prepared for sale and shipping. It is cut, packaged, labeled, and palletized into boxes for distribution.